In the rapidly evolving industrial landscape, the demand for efficient and reliable automation systems has never been greater. Automatic valves are pivotal in various applications, including water treatment, oil and gas, and manufacturing processes, to regulate flow and pressure with precision. According to a recent report by MarketsandMarkets, the global market for automatic valves is expected to reach USD 25.7 billion by 2026, growing at a CAGR of 6.8%. As industries strive to enhance operational performance and reduce downtime, implementing robust strategies for improving performance and reliability in automatic valve systems becomes essential. This blog outlines a comprehensive checklist of best practices, driven by industry insights and technological advancements, aimed at optimizing the functionality and lifespan of automatic valves, ensuring they meet the rigorous demands of today’s automated environments.

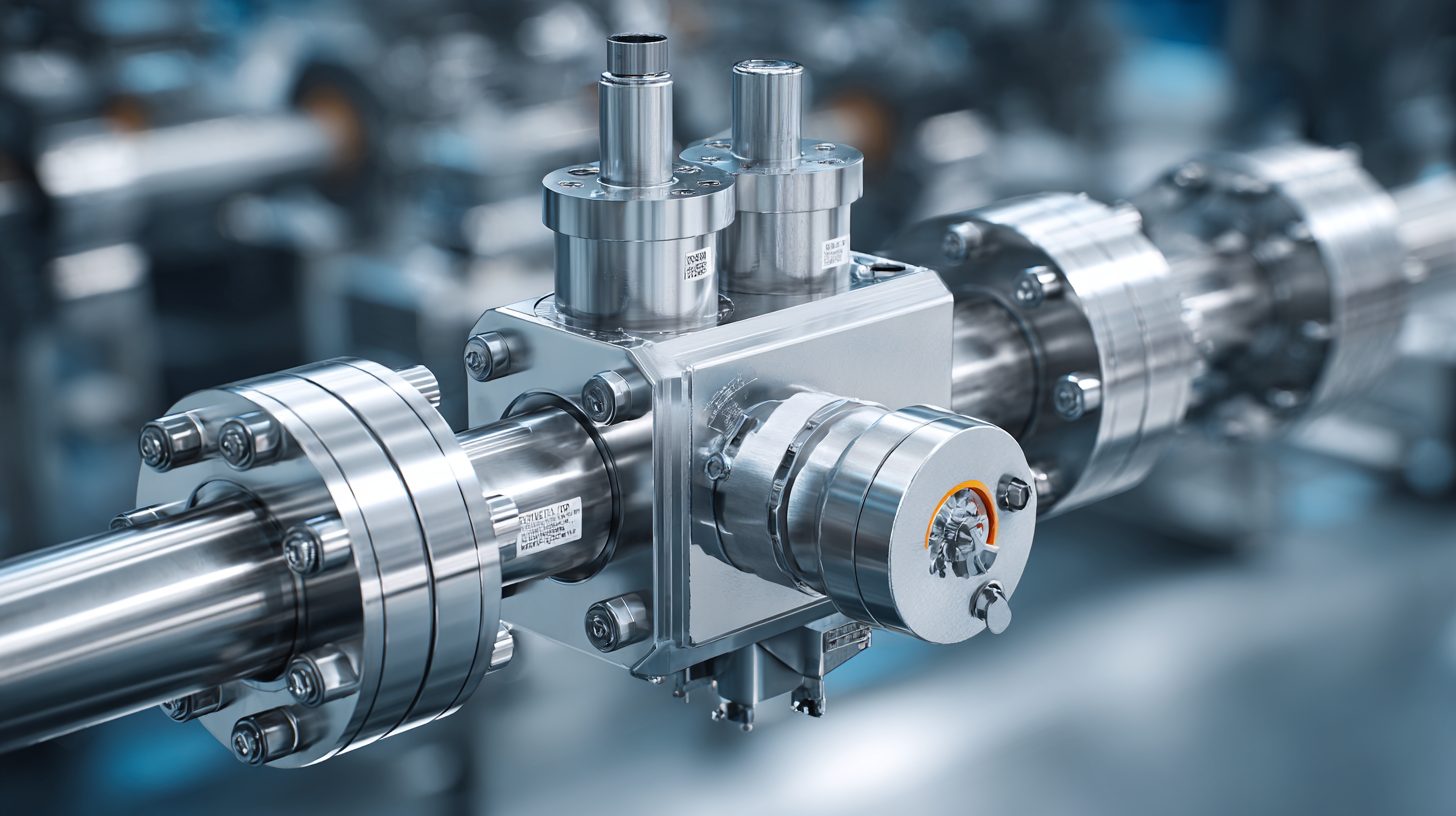

In the evolving field of industrial automation, exploring alternative technologies for automatic valve systems has become increasingly essential. Traditional pneumatic and hydraulic systems, while effective, often come with drawbacks such as high maintenance costs and environmental concerns. As industries resume their demand for efficiency, alternative technologies like electric actuators and smart valves are gaining traction. Electric actuators, known for their precision and minimal maintenance requirements, enable seamless integration with modern digital control systems, thus improving overall operational performance.

Another promising direction is the integration of IoT (Internet of Things) technology into automatic valve systems. Smart valves equipped with sensors and connectivity options can provide real-time data analytics, enhancing reliability and enabling predictive maintenance solutions. This proactive approach not only reduces downtime but also extends the lifespan of valve systems. By leveraging these alternative technologies, industries can enhance the performance and reliability of their automatic valve systems while contributing to more sustainable and efficient practices.

| Strategy | Technology Type | Performance Improvement (%) | Reliability Rating (1-10) | Implementation Complexity (1-5) |

|---|---|---|---|---|

| Predictive Maintenance | IoT Sensors | 20% | 9 | 3 |

| Automated Control Systems | AI Algorithms | 30% | 8 | 4 |

| Remote Monitoring | Cloud Computing | 15% | 7 | 2 |

| Enhanced Material Selection | Corrosion-Resistant Alloys | 25% | 9 | 2 |

| Flow Simulation Analysis | CFD Software | 18% | 8 | 4 |

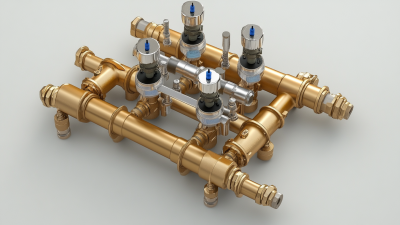

When evaluating performance metrics in different valve alternatives for automatic valve systems, it’s essential to consider several key factors that can significantly influence operational efficiency. Flow coefficient (Cv) is a critical metric, providing insights into the valve's capacity to allow fluid to pass through. Higher Cv values indicate better flow characteristics, which can lead to improved system performance. Different valve types, such as globe, ball, and gate valves, present varying Cv values, making it imperative to select the right valve for specific applications to optimize workflow and minimize energy loss.

Another important performance metric is pressure drop across the valve, which can affect overall system reliability and efficiency. A valve that exhibits excessive pressure drop can lead to increased energy consumption and reduced performance of downstream equipment. Therefore, analyzing the pressure drop characteristics of various valve designs is crucial in attaining a balance between performance and reliability. Additionally, actuation speed and response time are vital for applications requiring precise control. By thoroughly assessing these metrics, engineers can make informed decisions that align with the operational demands of their automatic valve systems, ensuring enhanced performance and long-term reliability.

This chart illustrates the flow rate performance of various valve types used in automatic valve systems. The performance metrics are critical for evaluating reliability and efficiency in different applications.

In the realm of automatic valve systems, implementing robust maintenance strategies is paramount for enhancing reliability, particularly in alternative systems such as pneumatic and electric actuated valves. According to a report by the International Society of Automation (ISA), maintenance-related failures account for over 30% of unplanned downtime in industrial operations. This underscores the need for proactive maintenance approaches that can minimize disruptions and improve overall system performance.

One effective strategy is to integrate predictive maintenance practices, leveraging data analytics to monitor valve performance in real-time. This allows for the early detection of anomalies and potential failures before they escalate into costly breakdowns. Industry experts recommend utilizing condition monitoring tools to track metrics like valve cycling frequency and actuator response times, ensuring that maintenance teams can address issues promptly.

Tip: Schedule regular training sessions for maintenance personnel on the latest valve technologies and diagnostic tools to ensure they are equipped with the skills needed for effective troubleshooting and repairs.

Additionally, employing a comprehensive maintenance schedule that includes routine inspections and performance testing can dramatically enhance the reliability of automatic valve systems. A study conducted by McKinsey & Company revealed that organizations with a structured maintenance program can experience up to 25% increase in equipment lifespan.

Tip: Implement a digital management system to track maintenance activities and outcomes, streamlining the process and enabling data-driven decision making for future maintenance needs.

When it comes to automatic valve systems, selecting the right alternative can significantly impact not just performance, but also the overall cost efficiency of operations. Conducting a thorough cost-benefit analysis is crucial in identifying which valve solution offers the best return on investment. Factors such as initial purchase price, installation costs, and maintenance requirements should be weighed against the expected operational lifespans and performance capabilities of the systems.

In evaluating different automatic valve options, it is essential to consider the long-term benefits they provide. While a less expensive valve may seem attractive initially, it may incur higher maintenance costs or provide inferior control precision over time. On the other hand, investing in higher-quality automatic valves, despite their upfront expense, can lead to enhanced reliability and reduced operational disruptions. This strategic evaluation not only aids in budget management but also aligns with the overall efficiency goals of the operation, ensuring that the selected valves can withstand the specific demands of the processes they serve.

In the quest for enhanced performance and reliability in automatic valve systems, integrating alternative valve solutions has emerged as a pivotal strategy. According to a report by Research and Markets, the global automatic valve market is projected to reach $25 billion by 2027, with an increasing emphasis on automation and smart technologies. Innovative alternatives like electro-hydraulic and pneumatic actuators are now being integrated into existing systems, significantly improving responsiveness and reducing energy consumption by up to 30%. This shift not only maximizes operational efficiency but also aligns with evolving industry standards for sustainability.

Tip: When considering alternative valve solutions, it's crucial to assess the compatibility with existing systems. A thorough compatibility analysis can prevent costly downtime and enhance system integrity. Additionally, leveraging technologies such as predictive maintenance can further bolster reliability, reducing the likelihood of unexpected failures by up to 40%, according to a study by the International Journal of Engineering.

Another innovative approach is the use of smart valves equipped with IoT capabilities, enabling real-time monitoring and control. Research from Frost & Sullivan highlights that smart valve systems can increase operational efficiency by improving decision-making processes through data analytics. By adopting these state-of-the-art alternatives, industries can ensure not only improved performance but also a more resilient and responsive infrastructure that meets today's demanding operational requirements.