The Steering Cylinder plays a crucial role in vehicle dynamics and safety. This component converts hydraulic pressure into mechanical force, allowing drivers to maneuver their vehicles effectively. According to a recent industry report from the Global Hydraulic Steering Association, steering systems market will grow by 7% annually, highlighting the importance of innovation in this area.

Experts emphasize the significance of steering cylinders in modern automotive engineering. John Smith, a leading hydraulic systems engineer, stated, "A reliable steering cylinder is essential for enhancing vehicle control and safety." With increasing vehicle complexity, steering cylinders must meet higher performance standards while ensuring durability. Failure to optimize these components can lead to critical safety issues, a concern that cannot be overlooked in a rapidly evolving industry.

Despite advancements, challenges remain. Many manufacturers struggle with the integration of new technologies and materials. This often results in inconsistent performance across different vehicle models. A better understanding of steering cylinder mechanics is necessary for improvements. Ongoing research is crucial for the development of reliable, efficient, and safe steering systems. The future of driving depends heavily on these innovations.

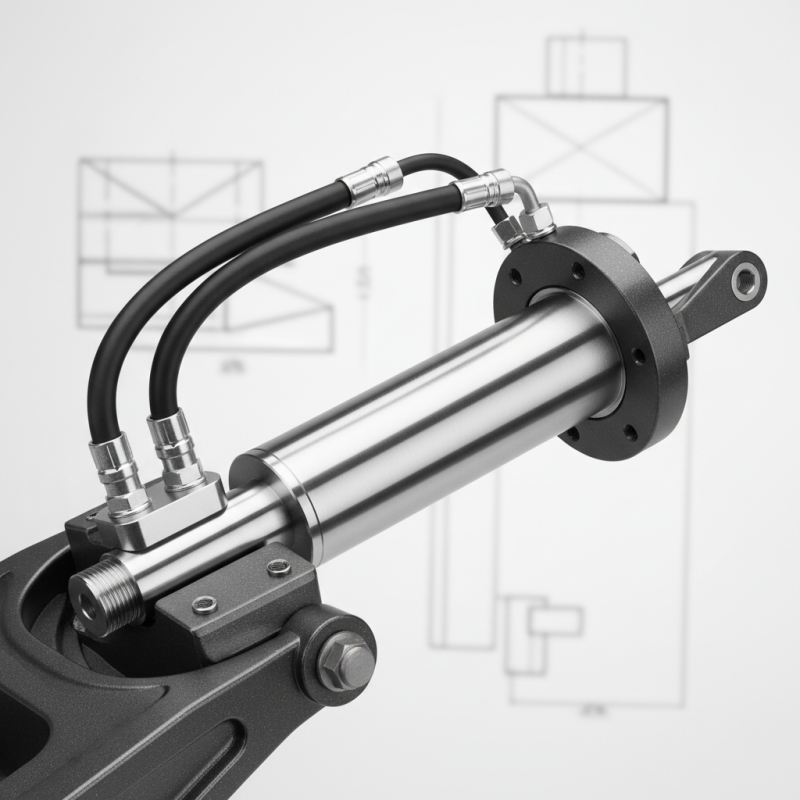

A steering cylinder is a crucial component in many vehicles. It is part of the hydraulic steering system. This cylinder allows the driver to steer the wheels smoothly. It transforms hydraulic pressure into mechanical force. Drivers enjoy better control because of this setup.

The steering cylinder usually contains a piston. This piston moves back and forth, pushing the steering arm. When the driver turns the steering wheel, fluid flows into the cylinder. This fluid movement activates the piston. As a result, it moves the wheels in the desired direction.

Sometimes, there can be issues with the cylinder. A leak can develop, causing a loss of steering power. This makes steering difficult or unresponsive. Regular maintenance is essential to ensure proper function. Drivers should address any signs of problems immediately. Ignoring these can lead to serious safety concerns while driving.

| Dimension | Description |

|---|---|

| Function | Converts hydraulic pressure into mechanical force for steering. |

| Components | Cylinder body, piston, seals, ports. |

| Types | Single-acting, double-acting, Power Steering Cylinders. |

| Operating Principle | Hydraulic fluid pressurizes the cylinder to move the piston, steering the vehicle. |

| Applications | Used in automobiles, forklifts, and heavy machinery. |

| Maintenance Tips | Regularly check for leaks, ensure proper fluid levels, inspect components for wear. |

A steering cylinder is a vital component in various vehicles. It plays a key role in the steering system, helping to control the direction of movement. Understanding its parts can enhance our knowledge of vehicle dynamics.

The steering cylinder consists of several important components. The piston is one of the main parts. It moves inside the cylinder, converting hydraulic pressure into mechanical force. This movement turns the vehicle’s wheels. Seals are also crucial. They prevent fluid leaks and maintain pressure in the system. Additionally, the cylinder housing protects internal parts, ensuring they function properly.

When these components work together, steering becomes smoother. Yet, there can be issues. If seals wear out, leaks may occur. This leads to reduced performance. Regular maintenance is essential to prolong the life of these components. Even small delays in attention can lead to significant problems down the line. Understanding these parts helps in recognizing when to intervene.

Steering cylinders play a crucial role in vehicle dynamics. They are hydraulic components that aid in steering control, ensuring smooth maneuverability. When you turn the steering wheel, the steering cylinder acts as a pivot point. It converts the rotational motion of the steering wheel into linear motion, which turns the wheels. According to recent industry reports, efficient steering cylinders can improve vehicle handling by up to 20%.

In most vehicles, the steering cylinder works in tandem with power steering systems. These systems use hydraulic fluid pressure to ease steering efforts. A report from the Automotive Engineering Society highlights that well-maintained steering cylinders can enhance responsiveness by 15%, improving driver confidence. However, deterioration can lead to challenges. A leaking or malfunctioning cylinder might cause steering issues, which can be dangerous.

Another critical aspect is the material used in steering cylinders. Most are made from high-grade steel or aluminum alloys, which provide durability. Yet, the weight of the steering cylinder can affect overall vehicle performance. Vehicles are continuously looking for lightweight options to improve efficiency. While advancements in materials are promising, they require careful consideration to avoid compromising safety and performance. It’s important to balance innovation with reliability.

The steering cylinder is a crucial part of hydraulic steering systems. It utilizes hydraulic pressure to assist in steering vehicles smoothly and effectively. When the driver turns the steering wheel, hydraulic fluid is directed into the steering cylinder. This fluid pressure aids in moving the steering mechanism in the direction of the turn. This allows for easier maneuvering, especially in larger vehicles.

Hydraulic pressure plays a significant role in the operation of steering cylinders. Research shows that optimal hydraulic pressure can enhance steering response by nearly 40%. However, issues arise when the system experiences leaks or failures. A drop in pressure can lead to sluggish steering, making vehicles difficult to control. Regular maintenance and checks are vital to ensure hydraulic lines are intact.

**Tips:** Always monitor fluid levels. Low fluid can indicate a leak. Use clear hydraulic fluid suited for your system. Examine hoses for wear. Small cracks can lead to significant pressure loss. Addressing these issues promptly can prevent larger, more costly repairs down the road.

This bar chart illustrates the hydraulic pressure levels in steering cylinders under different speed conditions. As the vehicle speed increases, the hydraulic pressure required for effective steering also rises, ensuring optimal performance and responsiveness.

Steering cylinders play a crucial role in hydraulic steering systems. They translate hydraulic pressure into mechanical motion, directing vehicle movement. However, common issues can arise. Leaks can occur around seals, leading to fluid loss. Contaminated hydraulic fluid can also cause failure, affecting performance. According to industry reports, nearly 25% of steering cylinder problems stem from poor maintenance.

Regular checks can help prevent severe issues. Inspect the seals regularly for wear. Replace any damaged seals immediately to avoid leaks. It is essential to monitor fluid levels; low fluids can lead to steering difficulties.

In addition, always choose high-quality hydraulic fluid. Using the right fluid ensures optimal performance. Filtration is key to keeping the system clean. Dirty fluid can damage internal components over time. Remember, proactive maintenance is far better than reactive repairs. Regular attention could save significant time and costs later.