In the intricate realm of fluid systems, mastering the art of flow regulation is paramount for achieving optimal performance and efficiency. Flow regulators play a crucial role in managing the speed and volume of fluid traversing pipelines and machinery. Whether in industrial applications, HVAC systems, or chemical processing, the ability to maintain consistent flow rates can significantly impact system reliability and energy consumption.

In this guide, we will explore essential tips that will empower engineers and technicians to effectively harness the capabilities of flow regulators. From understanding the principles of flow dynamics to selecting the right type of regulator for specific applications, we will provide actionable insights that ensure precision control and enhanced performance in fluid systems. Whether you are a seasoned professional or a newcomer in the field, the following strategies will equip you with the knowledge necessary to optimize your workflow and enhance the longevity of your systems.

Fluid flow is a fundamental aspect of various systems, from industrial processes to everyday applications. Understanding the basics of fluid dynamics, including the principles governing fluid movement, is crucial for effective regulation. Fluid flow is influenced by factors such as pressure, temperature, and the physical properties of the fluid itself. By grasping concepts like viscosity, flow rate, and the continuity equation, operators can predict how fluids behave within a system. This foundational knowledge enables enhanced decision-making when designing and managing fluid systems.

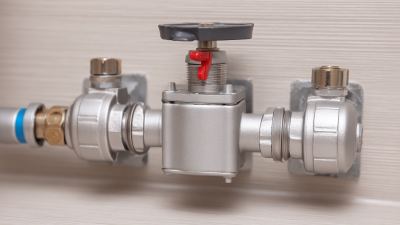

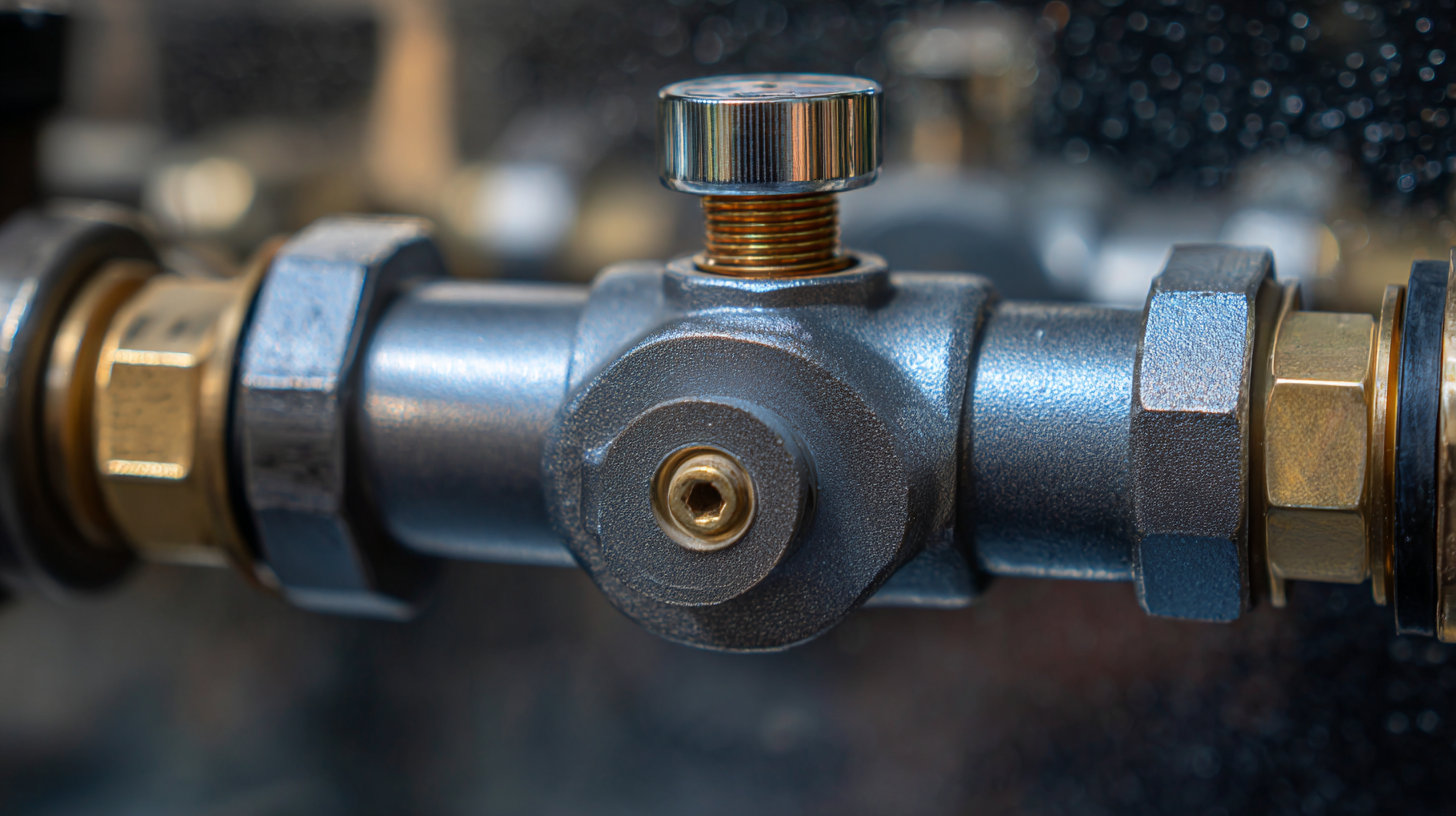

Regulation techniques play a pivotal role in maintaining optimal performance. Implementing control mechanisms such as valves, pumps, and flow meters allows for precise adjustments to fluid flow. Techniques like feedback control and PID (Proportional-Integral-Derivative) controllers can further improve system responsiveness and efficiency. Utilizing these strategies not only mitigates the risks of overpressure or inadequate flow but also contributes to energy savings and process optimization. By mastering these fundamental aspects of fluid flow and regulation, professionals can ensure their systems operate at peak performance while minimizing downtime and maintenance costs.

In fluid systems, several key components significantly influence performance and efficiency. According to a report by the Hydraulic Institute, approximately 30% of energy is lost in hydraulic systems due to inefficiencies in pump selection and sizing. Properly selecting and sizing pumps ensures optimal flow rates and minimizes energy loss. Additionally, the report highlights that using variable frequency drives (VFDs) can enhance control over fluid flow, leading to up to a 50% reduction in energy consumption under variable load conditions.

Another critical factor is the design and condition of pipes and fittings. The International Journal of Fluid Mechanics Research emphasizes that friction losses due to poor pipeline design can account for as much as 20% of total energy expenditures in a fluid system. By utilizing advanced computational fluid dynamics (CFD) simulations, engineers can optimize pipe diameters and configurations, reducing these losses and ensuring smoother flow. Regular maintenance of these components also plays a vital role; systems that undergo routine checks and repairs can improve their overall efficiency by as much as 15%, as noted by the American Society of Mechanical Engineers (ASME). Understanding these components and their interactions is essential for professionals aiming to master flow regulation in fluid systems.

Implementing smart controls in fluid systems is crucial for achieving optimal flow management and enhancing overall performance. Smart controls utilize advanced algorithms and real-time data analytics to monitor and adjust flow rates dynamically. By integrating sensors and automated control systems, operators can respond promptly to changing conditions, ensuring that the fluid maintains its desired path and pressure. This approach not only improves efficiency but also reduces the risk of system failures associated with erratic flow patterns.

Moreover, the application of machine learning and artificial intelligence in flow regulation can significantly enhance decision-making processes. These technologies can predict potential issues by analyzing historical data and current system behaviors, allowing for proactive maintenance and adjustments. For example, predictive analytics can identify trends that may lead to flow disruptions, enabling operators to take corrective measures before they escalate into critical problems. As we continue to advance in the field of fluid management, embracing smart control technologies will be pivotal in maximizing performance and sustaining operational excellence.

Regular maintenance is crucial for ensuring optimal flow regulation in fluid systems, especially in complex environments such as power plants. By implementing a routine maintenance schedule, operators can identify and resolve potential issues before they escalate into major failures. This may include checking the integrity of piping, ensuring control valves operate smoothly, and calibrating flow meters to ensure accuracy. A proactive approach not only enhances system efficiency but also prolongs the lifespan of critical components.

To enhance the performance of pumping systems, adopting modern technologies is essential. Innovations such as advanced monitoring and automation systems allow for real-time adjustments in fluid flow, significantly improving energy efficiency. Furthermore, adherence to established standards, like the ISA-75 series, ensures that control valve design and testing align with best practices. This commitment to excellence in maintenance and operation ultimately leads to superior flow regulation, supporting overall facility performance and reliability.

| Maintenance Practice | Frequency | Benefits |

|---|---|---|

| Regular Cleaning | Monthly | Prevents buildup that may restrict flow |

| Seal Inspection | Quarterly | Ensures no leaks and maintains pressure |

| Flow Rate Monitoring | Weekly | Detects irregularities in performance |

| Filter Replacement | Biannually | Maintains cleanliness of fluid, ensuring efficiency |

| Fluid Quality Testing | Annually | Identifies contamination issues |

| Equipment Calibration | Annually | Ensures measuring devices are accurate |

In the realm of fluid systems, effective flow regulation is crucial for optimizing performance and mitigating common challenges. The global control valve market, which plays a significant role in flow regulation, is projected to grow from $9.83 million in 2024 to approximately $14.71 million by 2032, representing a compound annual growth rate (CAGR) of 5.1%. This growth signifies an increasing need for advanced technologies and strategies to enhance flow control in various applications from industrial processes to environmental management.

However, industries often face challenges such as fluctuating pressure levels, undesirable flow patterns, and valve performance inconsistencies. For instance, a risk monitoring platform built on real-time computation and intelligent algorithms represents a novel approach to address these issues, facilitating comprehensive risk oversight in fluid systems. Such innovations can significantly improve the accuracy of flow measurements and enhance overall system reliability, as confirmed by research indicating that incorporating sophisticated analytics can lead to better resource allocation and operational efficiency.

Moreover, technologies like ultra-fast network flow algorithms demonstrate potential solutions for maximizing throughput while minimizing transmission costs, reinforcing the importance of integrating cutting-edge methodologies into flow regulation practices. By focusing on these developments, organizations can better navigate the complexities of fluid system management and achieve optimal performance.