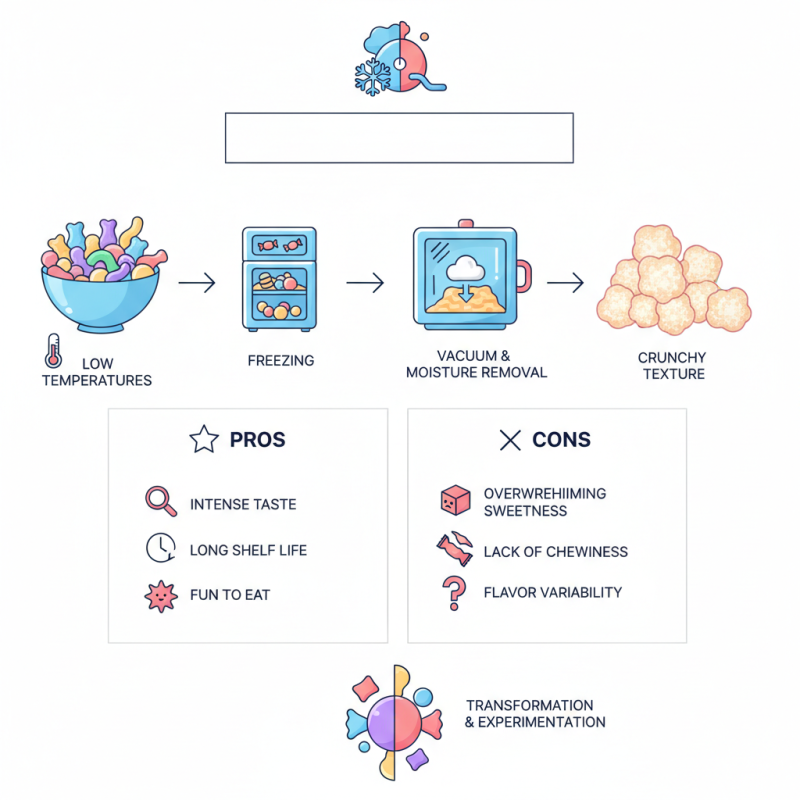

Freeze Dry Candy is a delightful treat that has gained popularity in recent years. It is unique because it retains the flavor and shape of the original candy. The process of creating this candy is fascinating. It starts by freezing the candy at low temperatures. After that, moisture is removed through a vacuum. This results in a light, crunchy texture.

Many people enjoy Freeze Dry Candy for its intense taste. Not only is it fun to eat, but it also has a long shelf life. However, the sweetness can sometimes feel overwhelming. The airy, crisp texture may leave some craving the original, chewy version. Each bite is an adventure, yet some flavors don’t translate well after freeze drying.

In exploring this candy, we can appreciate both its magic and its limitations. Every piece tells a story of transformation, from gooey sweetness to airy delight. Each experiment brings surprises, challenging our expectations. Freeze Dry Candy invites us to experience familiar flavors in new ways, but it also reminds us that not all creations can be perfect.

Freeze-dry candy is a unique treat that captivates many with its airy texture and vibrant flavors. It’s made through a special process called freeze-drying, which involves removing moisture from the candy while preserving its shape and taste. This method allows the candy to retain its original flavors, even enhancing some. As you bite into it, the candy crumbles and almost melts in your mouth.

The freeze-drying process is fascinating yet complex. First, the candy is frozen to extreme temperatures. Then, it's placed in a vacuum chamber. This combination removes water crystals while leaving the candy intact. The result is a light, crunchy snack that’s different from traditional candies. However, the process can sometimes lead to inconsistencies. Some candies may lose their original flavor through this method. Others can become too fragile or overly sweet.

Creating freeze-dry candy can be an experiment. The choice of ingredients directly impacts the outcome. For example, chocolate may not freeze-dry as well as fruits. Each batch can teach valuable lessons about texture and taste. Over time, one learns which combinations work best and which do not.

Freeze dry candy has gained popularity for its unique texture and fun flavors. The process of making freeze dry candy is both fascinating and intricate. It starts with a variety of candies, often gummies or marshmallows, which are prepared for freeze drying. The first step is to freeze the candy at extremely low temperatures, usually around -40 degrees Celsius. This process locks in the candy's flavor while allowing moisture to be removed.

Once frozen, the candy undergoes sublimation. In this phase, pressure is reduced, turning the ice directly into vapor. This step is crucial as it enables the candy to retain its shape and achieve that signature lightweight texture. According to recent industry reports, the freeze-dried sweets market is expected to grow at a compound annual growth rate of 11% over the next five years. This figure reflects a rising consumer interest in innovative candies.

However, making freeze dry candy is not without its challenges. Maintaining consistent temperature and pressure levels is critical. Any fluctuations can lead to uneven drying, resulting in candy that may be chewy rather than crispy. Some manufacturers report that achieving the perfect texture requires multiple trials and adjustments. Experimenting with different candies can also yield unexpected results, adding excitement and unpredictability to the process.

| Ingredient | Description | Benefits |

|---|---|---|

| Fruits | Fresh fruits like strawberries, bananas, and apples are commonly used. | Retains nutritional value and flavor, lightweight. |

| Sugar | Granulated sugar is added for sweetness. | Enhances flavor and improves preservation. |

| Corn Syrup | Used to improve texture and prevent crystallization. | Provides a chewy consistency. |

| Natural Flavorings | Extracts like vanilla or citrus zest may be added. | Enhances overall taste profile. |

| Freeze Dryer | Machine that removes moisture from products under vacuum. | Ensures longevity and preserves structure. |

Freeze dry candy is a popular treat made through a unique process. The key to its delicious texture lies in the ingredients used. The primary components are fruits, sugar, and sometimes flavorings. Fruits like strawberries and bananas are often chosen for their sweetness and vibrant colors. These fruits are sliced and prepared for freeze-drying.

Sugar plays a vital role. It acts as a preservative, helping to maintain the candy's flavor and texture. Studies show that sugar content in freeze-dried candies can range from 30% to 60%. This high sugar content adds to the candy's overall sweetness and intensity. Additionally, natural flavorings or color enhancers may be added, but consumers often prefer clean labels. Many seek out products that are free of artificial additives.

The freeze-drying process itself is fascinating. It removes moisture while retaining the fruit’s original flavor and nutrients. However, this process can be tricky. If done improperly, the texture can become overly crunchy or too soft. Monitoring temperature and pressure is essential for achieving that perfect balance. Unintended variations can affect the final product, leading to reflections on the importance of precision in the candy-making process.

Freeze dry candy has gained significant popularity due to its unique features and numerous benefits. One standout characteristic is its long shelf life. According to industry reports, freeze-dried products can last up to 25 years when stored properly. This makes them a perfect choice for emergency preparedness and outdoor enthusiasts.

Another benefit of freeze-dried candy is the preservation of taste and nutrients. The freeze-drying process removes moisture while retaining the original flavors. This results in a snack that is not only delicious but also maintains a high nutritional value. Studies show that freeze-drying can preserve as much as 97% of vitamins and minerals in fruits. This preservation method also intensifies the flavors, offering a unique candy experience.

Despite its advantages, consumers should note the texture differences. Freeze-dried candy tends to be lighter and crunchier than traditional options. Some people may find this unexpected. The candy can also absorb moisture quickly after opening, which alters its quality. Proper storage in an airtight container is crucial to maintain its desirable attributes. While these nuances may seem minor, they are essential for an optimal freeze-dried candy experience.

Freeze dry candy has become increasingly popular for its unique texture and flavor. Many varieties appeal to different tastes. Fruity options, like strawberries and bananas, offer a burst of sweetness. These flavors stay bright and vibrant, making them a favorite for both kids and adults.

Chocolate lovers can also enjoy freeze dried treats. Chocolate bites have a delightful crunch, enhancing the candy experience. There’s even a mix of fruit and chocolate, combining the best of both worlds. Some flavors are adventurous, like spicy mango, which adds an unexpected twist. The creative possibilities are endless, but not all combinations are successful.

Crafting freeze dry candy can be an experiment. Sometimes, flavors clash or textures don’t come out right. That’s part of the fun. Learning what works best may take time and patience. Each attempt offers a chance to reflect and refine. It’s all about the journey of discovering new favorites.