When searching for butterfly valves for sale, making informed choices is vital. The market is vast, with various options available. Knowing specifics can save you time and money.

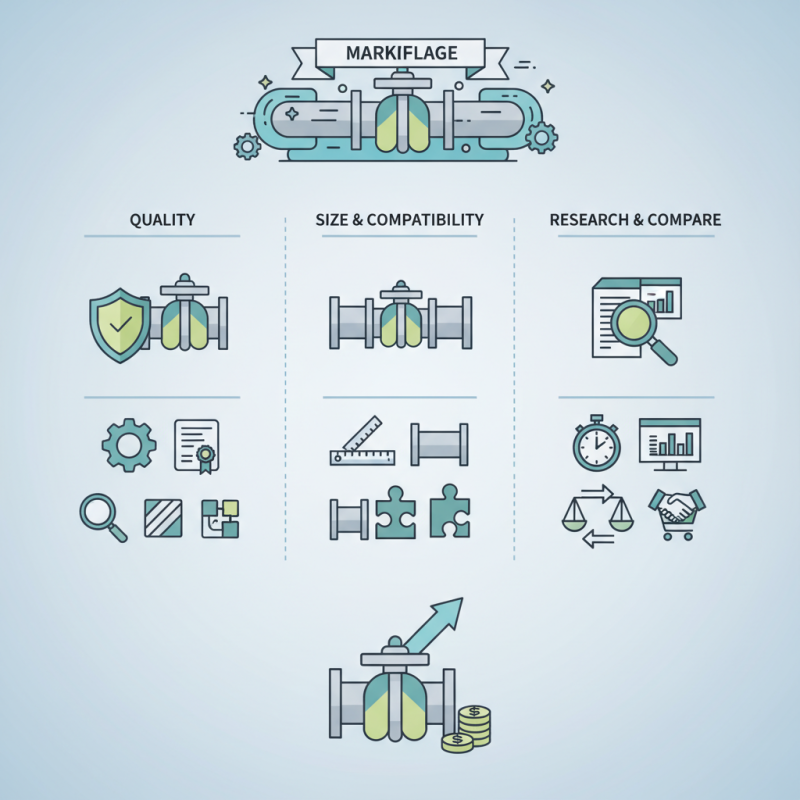

Quality is key when selecting butterfly valves. Look for trusted brands that have a solid reputation. Inspecting product materials can reveal whether they meet industry standards. You should also consider the size and compatibility with your existing systems.

Sometimes, buyers rush the process, leading to regrets. Take time to research and compare options. Evaluate different suppliers and their offerings. A careful approach will ensure you invest wisely in butterfly valves that last.

When purchasing butterfly valves, understanding their types and functions is crucial. These valves are versatile devices used in various industries. The most common types include wafer, lug, and concentric designs. Each type serves different applications, from water systems to chemical processing. Wafer butterfly valves are lightweight and easy to install. Lug and concentric styles offer added benefits in specific scenarios, but may require more careful consideration.

The function of butterfly valves is primarily to regulate flow. They achieve this through a rotating disk that opens or closes the passageway. This mechanism is efficient, but it can sometimes lead to leakage if not properly maintained. Users should monitor their valves regularly to ensure they are not clogged or damaged. Installation can also pose challenges, such as aligning the valve correctly. Improper installation could lead to operational inefficiencies.

Examining the material of butterfly valves is critical too. Common materials include metal and plastic, offering different advantages. Metal valves provide durability but can corrode over time. Choosing the right material is vital to enhance longevity. Reflecting on these factors helps in selecting the best butterfly valve for your needs. Understanding these characteristics can assist in making an informed decision.

When it comes to buying butterfly valves, material choice is crucial. Aluminum is a lightweight option. It resists corrosion well but may not handle high temperatures. In contrast, stainless steel is far more robust. According to industry reports, stainless steel valves account for over 40% of the market share due to their strength and durability.

Consider the application before selecting a valve material. For instance, aluminum may suit water systems, but stainless steel works better in chemical processing. Misjudging this can lead to equipment failure. Data suggests that around 30% of maintenance issues stem from poor material choices, impacting operational efficiency significantly.

Other materials, like ductile iron, also have their place. They offer strength and impact resistance, especially in heavy-duty applications. However, not all projects demand heavy materials. Assess project requirements to avoid unnecessary costs. Flexibility in material choice can lead to better performance and lower expenses long-term.

When sizing butterfly valves, the diameter is crucial. It affects flow rates and system efficiency. Select a diameter that matches your pipeline requirements. Too small can restrict flow. Too large can create turbulence. This can lead to inefficiencies and higher energy costs.

To calculate the right diameter, consider your pipeline's flow rate. Measure the maximum flow you expect. This will guide you. Using valve sizing charts can help as well. Keep in mind pressure drop, as it influences performance. Make sure your calculations take into account various system conditions.

Here are tips to remember. Understand the medium you’ll be working with. Some fluids require specific valve materials. Always think about installation space. A valve that fits snugly is crucial. Finally, check for compatibility with existing fittings. This can save you from costly adjustments later on.

When buying butterfly valves, it's crucial to understand pressure ratings and flow coefficients. Pressure ratings indicate the maximum pressure the valve can handle. A valve with a higher pressure rating is typically more versatile. However, not every application requires a high rating. Knowing your system's pressure requirements is essential to avoid over-specifying.

Flow coefficients (CV) measure the valve's ability to pass fluid. A higher CV indicates better flow capacity. It's important to consider both the flow rate and fluid type in your application. Sometimes, a lower CV might suffice for specific scenarios. Misjudging these parameters can lead to inefficiencies or even system failures.

When selecting a butterfly valve, visualize your system's requirements. Consider the installation space, operating conditions, and maintenance needs. Balancing these factors can be tricky. A poorly chosen valve might affect overall system performance. So, reflect on the long-term implications of your selection carefully. The right choice will enhance efficiency and reliability, while a hasty decision may lead to regrets later.

When considering butterfly valves for sale, cost analysis plays a crucial role. Finding the right balance between quality and price is essential. A cheaper valve may come with hidden expenses. Low-quality materials can lead to quicker wear and tear. This will eventually cost more in replacements and maintenance.

Check the specifications carefully. Always ask about the materials used. Brass or stainless steel often indicates durability. Additionally, consider the valve's intended use. A valve intended for high-pressure environments requires rigorous standards. Opting for a cheaper valve in such situations could compromise functionality.

Tip: Look for reviews and testimonials. User experiences can reveal insights about expected lifespan and performance. Another important point is not to sacrifice quality for price alone. Sometimes, spending a bit more upfront saves money in the long run. Be mindful of warranties and support offered by suppliers. Neglecting these aspects can lead to frustration later on.