Enameled Aluminum Magnet Wire offers significant advantages in various applications. This specialized wire is coated with a thin layer of enamel, which serves as insulation. Its lightweight nature makes it ideal for electric motors and transformers.

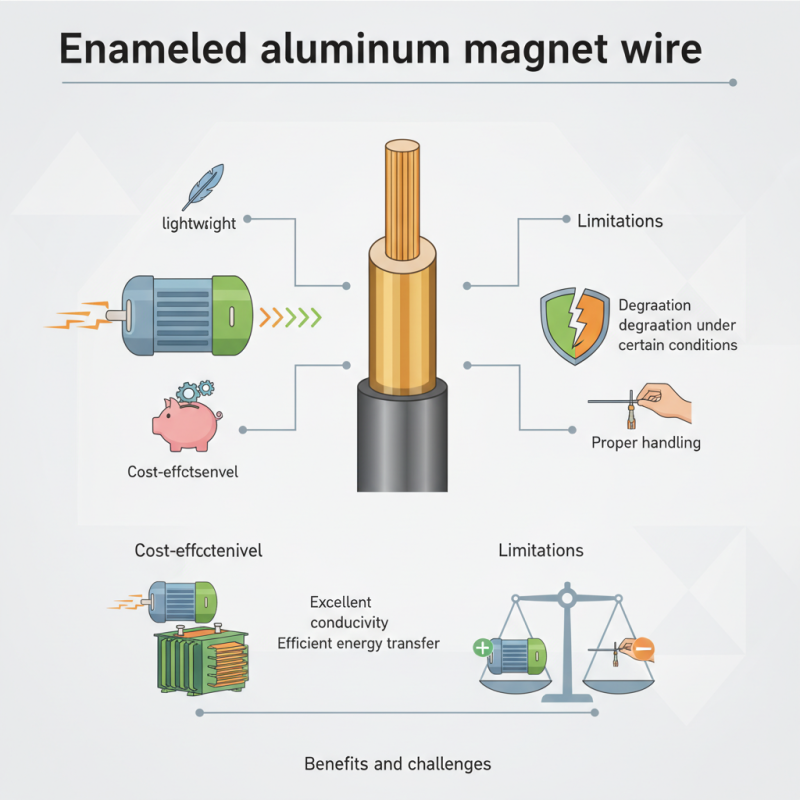

The benefits of using Enameled Aluminum Magnet Wire go beyond just weight. It boasts excellent conductivity, allowing for efficient energy transfer. Many industries have adopted this material for its cost-effectiveness. However, one must consider its limitations as well. The enamel coating may degrade under certain conditions. Proper handling and installation are essential to avoid potential issues.

In conclusion, Enameled Aluminum Magnet Wire presents a blend of benefits and challenges. Its distinctive properties make it a preferred choice, yet careful use is necessary. Understanding both the virtues and drawbacks can lead to better decisions in engineering and manufacturing processes.

Enameled aluminum magnet wire is an essential component in many electrical applications. It consists of a thin aluminum conductor coated with a layer of insulating enamel. This coating serves two primary purposes: preventing electrical shorts and protecting the wire from environmental factors. The enamel insulation allows for efficient energy transfer, making this wire ideal for motors and transformers.

One striking feature of enameled aluminum wire is its lightweight nature. Compared to copper, it reduces overall equipment weight significantly. However, there are challenges as well. Since aluminum is less conductive than copper, higher gauge wire is necessary for the same performance. This can lead to bulkier designs that may not fit all applications.

Additionally, the production process can introduce imperfections. Variations in insulation thickness may occur, affecting performance reliability. This is crucial in sensitive applications where precise energy control is needed. Users often face a trade-off between weight and efficiency. Ultimately, understanding the composition of enameled aluminum magnet wire can lead to better design choices and improved application performance.

Enameled aluminum magnet wire is essential for various electrical applications. Its lightweight and cost-effective nature makes it a popular choice. Used widely in electric motors, transformers, and generators, the wire exhibits excellent conductivity. This performance is vital for efficient energy transfer. In some cases, aluminum wire can outperform copper, especially in high-voltage situations.

The insulation on enameled aluminum wire helps prevent short circuits. However, using it requires care. The enamel coating may wear in harsh environments. Regular inspections can help maintain functionality. Some manufacturers struggle with the consistency of enamel quality, which can lead to performance issues. Despite this, many find its advantages, such as weight reduction and lower costs, offset potential drawbacks.

Applications also include consumer products like speakers and automotive parts. These uses highlight versatility but come with challenges. Ensuring compatibility with existing systems is crucial. Some users face difficulties with soldering due to aluminum's properties. Understanding these factors is key to optimizing performance. This balance between benefits and challenges is what makes enameled aluminum magnet wire an intriguing option in electrical engineering.

| Use Case | Benefits | Applications |

|---|---|---|

| Electric Motors | Lightweight, good conductivity | Automotive, industrial machinery |

| Transformers | Excellent thermal characteristics | Electrical grids, renewable energy |

| Generators | High efficiency, cost-effective | Wind turbines, hydroelectric systems |

| Robotics | Compact design, flexibility | Industrial robots, automation systems |

| Home Appliances | Affordable, reliable performance | Refrigerators, microwaves |

Enameled aluminum magnet wire offers several advantages over traditional copper wire. One crucial benefit is its lighter weight. Aluminum is significantly lighter than copper, making it easier to handle and install in various applications. This can reduce labor costs and improve efficiency during installation.

Another key advantage is cost-effectiveness. Aluminum wire tends to be less expensive than copper. The reduced material costs can lead to significant savings, especially in large-scale projects. However, some may worry about the conductivity difference. While aluminum has lower conductivity than copper, advancements in wire design help compensate for this.

Enameled aluminum is also more resistant to corrosion. This feature extends the lifespan of the wire in harsh environments. Some users feel uncertain about switching from copper to aluminum due to perceived reliability issues. Testing and experience can help clarify these concerns. When properly used, aluminum magnet wire can perform exceptionally well in various applications.

When choosing enameled aluminum magnet wire, several factors are crucial. The wire's insulation type directly influences its performance. Different applications may require different insulation ratings. For high-temperature settings, consider heavy-duty coatings. For typical use, standard insulation may suffice.

The wire gauge is another key factor. A thicker wire can handle more current, but it is also heavier and less flexible. When designing your project, find a balance between strength and flexibility. Always consider the physical space available and the wire's weight.

Tips: Verify the wire's conductivity. Enameled aluminum wire typically conducts less than copper. This aspect is significant for efficiency. Also, double-check bend radius specifications to prevent breakage.

Remember the wire's thermal properties. Aluminum has a different thermal expansion rate than other metals. Ensure your application accounts for this to avoid potential issues down the line.

Enameled aluminum magnet wire is commonly used in motors, transformers, and other electrical applications. Proper handling and installation are crucial to maximizing its performance and longevity. The wire is lightweight and has good conductivity. However, its insulation is sensitive to damage.

When cutting the wire, use appropriate tools to avoid nicks. Sharp tools reduce the risk of insulation breach. Maintain a clean workspace to prevent contaminants from affecting the wire.

Avoid excessive bending or twisting during installation. This can weaken the wire and shorten its lifespan. Instead, use appropriate techniques to guide the wire smoothly through tight spaces.

Tips: Always inspect the wire for any signs of wear before use. A small flaw can lead to significant issues in performance. Keep the wire away from sharp edges during storage. A little planning goes a long way.