Control valves play a crucial role in various industrial processes, serving as essential components that regulate the flow of fluids and gases to ensure optimal system performance. According to a report by MarketsandMarkets, the global control valve market is projected to reach USD 8.7 billion by 2023, growing at a compound annual growth rate (CAGR) of 6.4% during the forecast period. This growth can be attributed to the increasing demand for automation and process control across different sectors, including oil and gas, water and wastewater, and chemical manufacturing. Understanding the different types of control valves, such as globe valves, ball valves, and butterfly valves, along with their specific applications, is crucial for engineers and decision-makers to enhance efficiency and reliability in their operations. This blog will delve into the various types of control valves available in the market, their unique features, and how they can be effectively utilized in diverse industrial applications.

Control valves play an essential role in various industrial processes, regulating flow, pressure, and temperature across systems. Understanding the functionality and design of different types of control valves can greatly enhance operational efficiency. According to a report by Markets and Markets, the control valve market is expected to reach USD 12.4 billion by 2025, driven by the rising demand for automation in industries such as oil and gas, water treatment, and chemicals.

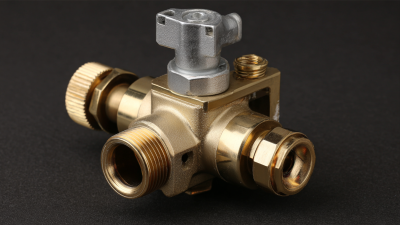

There are several key types of control valves, including globe, ball, gate, and butterfly valves, each designed for specific applications. Globe valves excel in throttling service, making them ideal for flow regulation, while ball valves provide quick shutoff capabilities, perfect for on/off applications. Research by Valves & Actuators shows that globe valves are projected to dominate the market due to their superior control capabilities, accounting for nearly 30% of total control valve sales in 2023. Conversely, butterfly valves are gaining popularity in applications requiring lightweight solutions with minimal pressure loss, showcasing the diversity in design tailored to meet specific operational needs.

Control valves are integral components in various industrial systems, providing precise flow regulation and maintaining desired operational conditions. Understanding the key features of different types of control valves, such as globe, ball, and butterfly valves, is crucial for optimizing performance in processes that demand accurate control over fluid dynamics. According to a report by MarketsandMarkets, the global control valve market is projected to reach $5.4 billion by 2025, highlighting the increasing reliance on these critical devices across diverse industries.

Globe valves, known for their excellent throttling capabilities, are often preferred in applications requiring fine control. They can effectively manage variations in flow and pressure, facilitating processes in oil and gas, chemical, and wastewater sectors. Conversely, ball valves, recognized for their quick operation and minimal pressure drop, are commonly employed in clean fluid applications where a tight seal and straightforward on/off control are essential. The versatility of butterfly valves makes them suitable for large volume flows in HVAC and water management systems, with the advantage of being lightweight and quick in action, thus enabling energy-efficient operations.

As industries evolve, the demand and application of these control valves continue to grow, underscoring their significance in enhancing system efficiency and reliability.

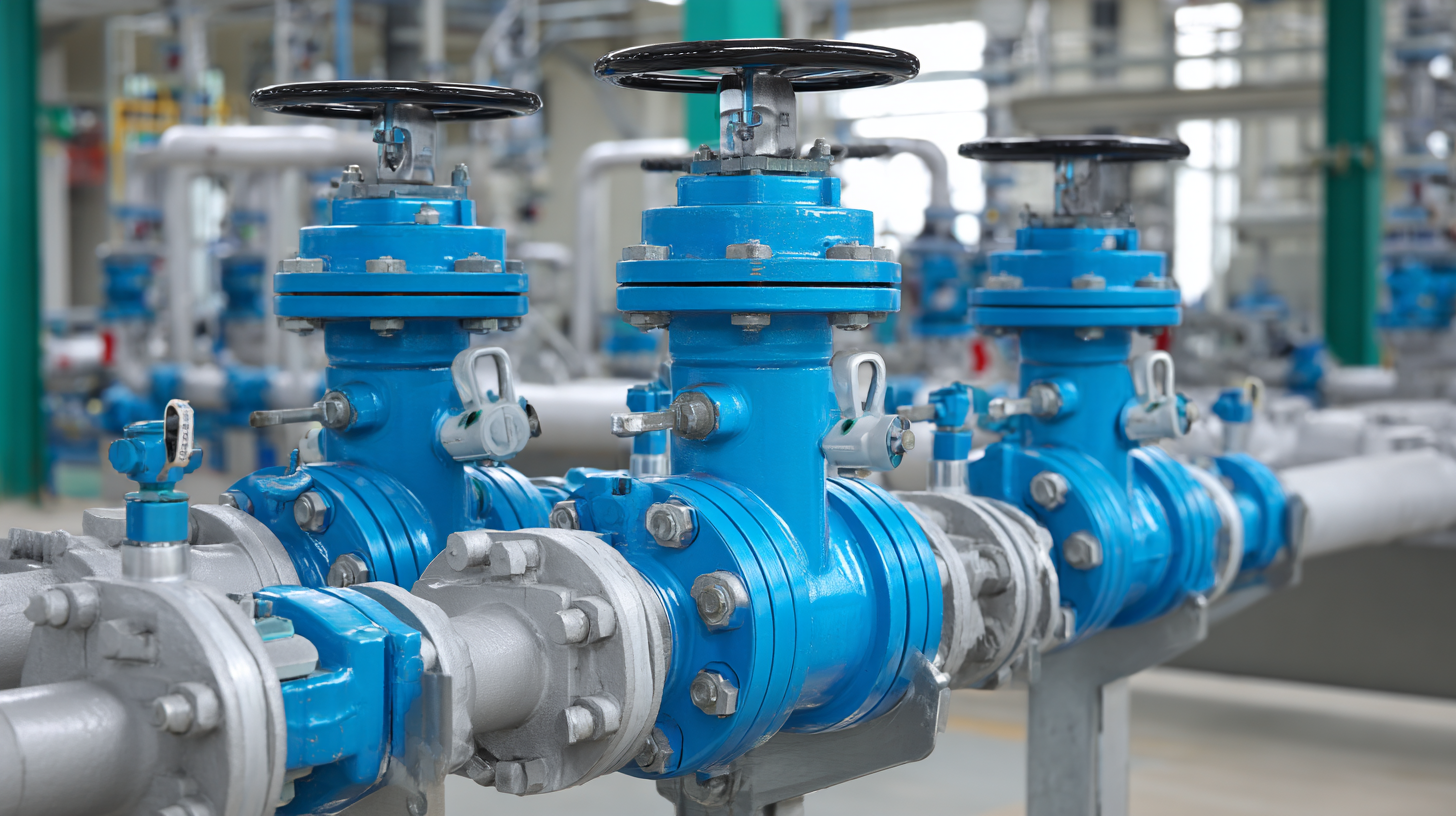

Control valves play an essential role across various industries by regulating the flow and pressure within piping systems. In the oil and gas sector, control valves manage the flow of crude oil and natural gas, which is critical for maintaining optimal operation and safety. According to the Global Control Valve Market Report, the oil and gas industry comprises approximately 40% of the total control valve market share, reflecting the vital importance of these components in ensuring efficient hydrocarbon transport and processing.

In the chemical manufacturing industry, control valves are similarly important. They help in maintaining the desired process conditions, which directly impacts product quality. A study by the Chemical Engineering Magazine indicated that improper control valve management can lead to a 20% increase in production costs due to inefficiencies. By utilizing advanced control valves, chemical plants can enhance their operational performance, thus driving down costs while increasing output. Additionally, with the growing emphasis on automation and digitalization, industries are leaning towards smart control valves, which offer real-time monitoring and improved reliability, further optimizing processes in sectors like pharmaceuticals and food and beverage.

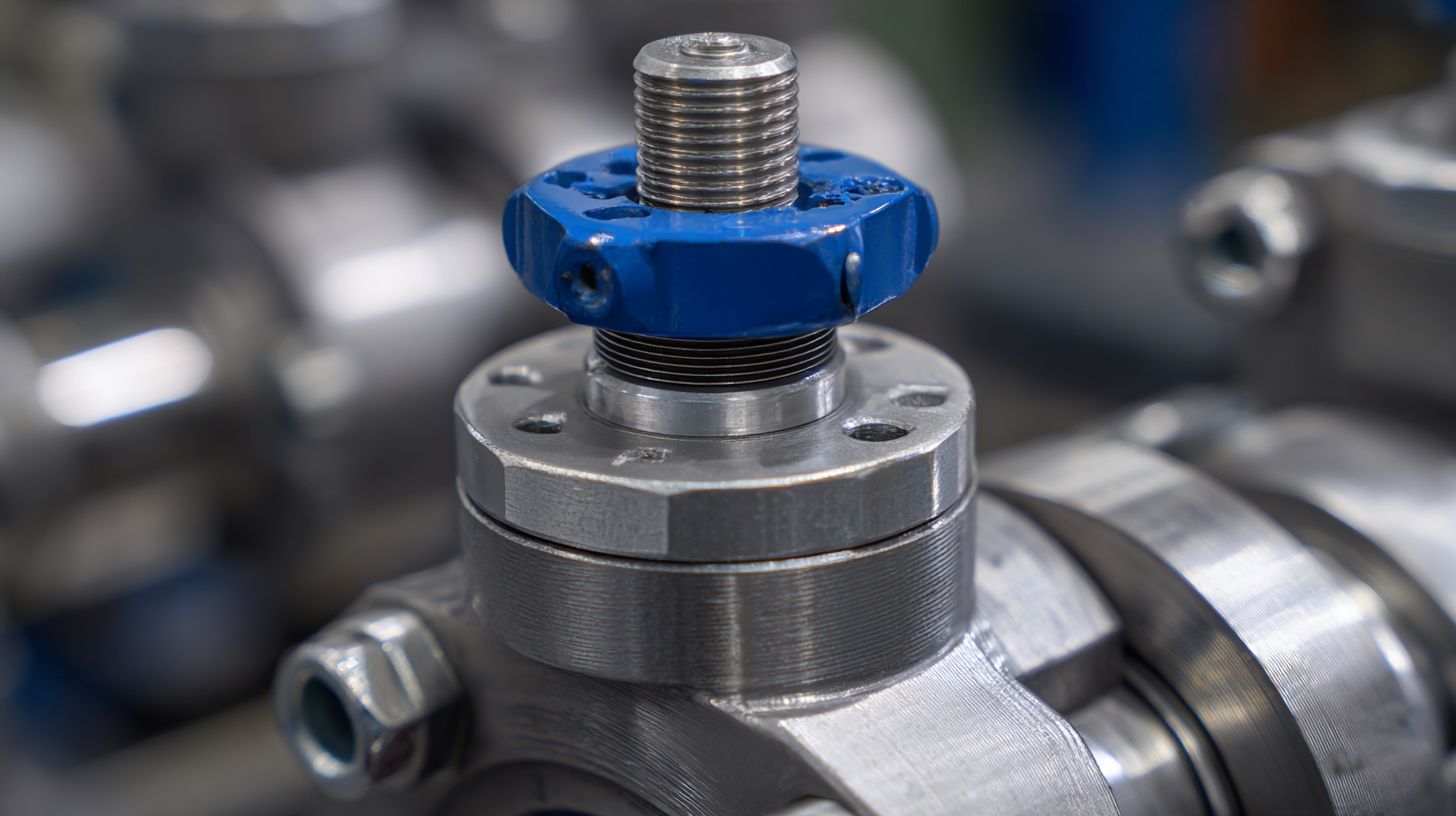

Choosing the right control valve is crucial for achieving optimal performance in any process system. Several factors should be considered to ensure that the selected valve meets the specific needs of an application. First and foremost, understanding the type of fluid being controlled is essential. Factors such as viscosity, temperature, and pressure can significantly impact the valve's performance. For instance, a control valve handling corrosive fluids may require special materials for construction to prevent damage and maintain integrity.

Another critical consideration is the valve's sizing and flow characteristic. A properly sized valve will regulate flow effectively without causing pressure drops that can affect system efficiency. Additionally, the flow characteristic — linear, equal percentage, or quick opening — must align with the process requirements to provide the desired response time and accuracy. Finally, factors such as control signal type, actuator type, and maintenance needs play pivotal roles in the selection process, ensuring that the control valve not only fits the immediate operational demands but also contributes to the longevity and reliability of the system.

| Valve Type | Description | Applications | Key Factors to Consider |

|---|---|---|---|

| Globe Valve | A valve with a spherical body that provides good flow control. | Steam, Water, Oil | Control accuracy, Pressure drop |

| Ball Valve | A valve that uses a spherical obstruction to stop or allow flow. | Gas, Water, Oil | Speed of operation, Tight sealing |

| Butterfly Valve | A valve that uses a rotating disc to regulate flow. | Pipelines, HVAC systems | Flow rate, Space requirements |

| Check Valve | A valve that prevents backflow in a system. | Water, Wastewater treatment | Pressure ratings, Fluid velocity |

| Pressure Relief Valve | A safety valve that opens to relieve pressure. | Boilers, Pressurized vessels | Pressure setting, Response time |

Control valves play a crucial role in various industrial processes, yet they often face operational challenges that can hinder efficiency and performance. One common issue is valve wear or failure, which can lead to leaks and downtime. According to the "2021 Control Valve Market Report," over 30% of control valve failures are attributed to improper sizing and selection. Ensuring that the valve is correctly sized for the application can significantly reduce wear and prolong its life. Regular maintenance schedules and predictive analytics, as highlighted in the "2022 Maintenance Strategies Study," can also help businesses identify potential issues before they escalate.

Another challenge is the phenomenon of valve oscillation, which can destabilize process control. This occurs when there is a mismatch between the valve's response time and the control system's settings. To mitigate this, it's recommended to analyze the dynamic response of control loops during the design phase, as emphasized in recent industry standards. Implementing advanced control algorithms can also aid in stabilizing performance and minimizing oscillations.

**Tips:** To enhance control valve performance, operators should utilize real-time monitoring systems. These can provide insights into valve behavior and alert maintenance teams to issues before they lead to more significant problems. Additionally, training personnel on the latest valve technologies can help them troubleshoot issues effectively, ensuring that they can perform timely interventions when necessary.