In today's evolving industrial landscape, the importance of choosing the right manufacturer for Thermostatic Blending Valves cannot be overstated. According to recent industry reports, the global thermostatic valve market is projected to reach USD 3.02 billion by 2025, growing at a CAGR of 7.8%. This significant growth is driven by the increasing demand for precise temperature control in various applications, including HVAC systems, manufacturing processes, and food and beverage production. A Thermostatic Blending Valve plays a pivotal role in these systems, ensuring optimal performance and energy efficiency. However, with numerous manufacturers vying for attention, understanding their offerings becomes crucial. This guide aims to illuminate the key factors to consider while comparing top manufacturers, providing insights into their product reliability, innovation, and industry applications, thereby facilitating informed decisions for end-users in a competitive market.

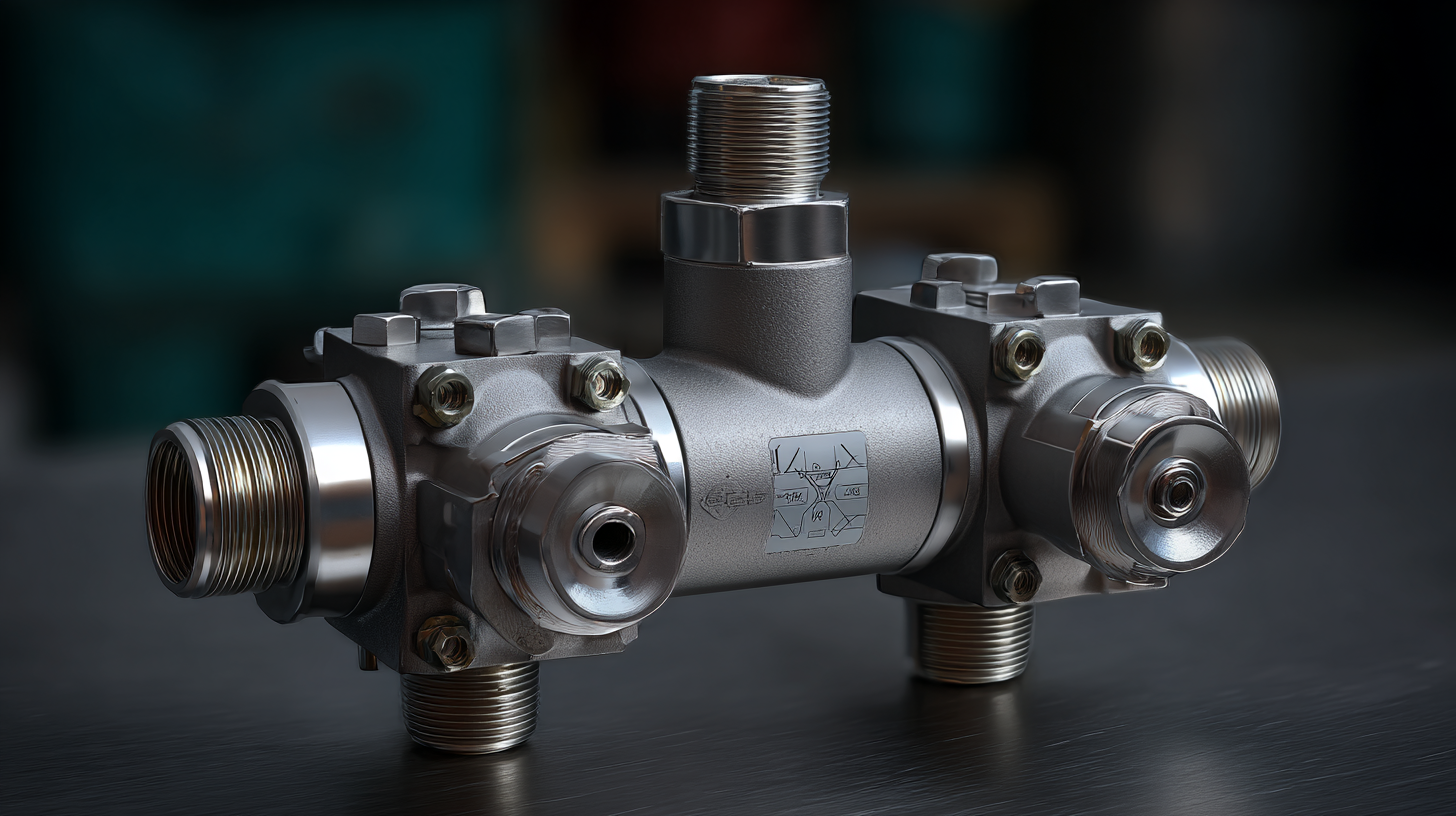

Thermostatic blending valves are essential components in modern plumbing systems, designed to regulate water temperature by mixing hot and cold water. These valves enhance safety by preventing scalding and ensure consistent water temperatures for various applications, from residential showers to industrial processes. Understanding the key features of these valves is crucial when selecting the right one for your needs.

When choosing a thermostatic blending valve, consider its response time and temperature accuracy. A quick response ensures that the valve adjusts the water temperature promptly, which is particularly important in environments where temperature fluctuations can cause discomfort or harm. Additionally, look for features such as built-in filters and anti-scald mechanisms to enhance safety and performance.

Tip: Regular maintenance of your thermostatic blending valve, including checking for blockages and ensuring that the temperature settings are accurate, can prolong its lifespan and maintain optimal performance.

Another vital aspect is the valve's compatibility with your existing plumbing system. Ensure that the valve can handle the pressure and flow rates specific to your setup.

Tip: Consulting with a plumbing professional can help you determine the best specifications for your system, ensuring you select a valve that meets all operational requirements efficiently.

When choosing the right manufacturer for thermostatic blending valves, understanding industry standards is crucial. Recent updates to plumbing codes highlight the importance of adhering to regulations that promote safety and efficiency. For instance, the International Plumbing Code has seen significant revisions aimed at improving the performance and reliability of these valves. As the demand for safe water temperature regulation grows, manufacturers must align their production practices with these evolving standards to ensure compliance and protect end-users from potential scalding hazards.

The thermostatic mixing valve market is on a promising trajectory, projected to reach $1.98 billion by 2035. This growth is largely driven by regulatory measures focused on anti-scald protection and the increasing adoption of green building practices. As such, manufacturers are encouraged to innovate and implement advanced technologies that not only meet regulatory requirements but also enhance energy efficiency. Understanding these dynamics enables buyers to make informed decisions when selecting a manufacturer, ultimately leading to improved safety and performance in plumbing systems.

When selecting a thermostatic blending valve, understanding the nuances of top manufacturers can significantly impact both quality and performance. According to a report by MarketsandMarkets, the global market for thermostatic blending valves is projected to reach $1.3 billion by 2027, driven by increasing demand for energy-efficient and sustainable heating solutions. Manufacturers like Honeywell and Danfoss lead the charge, known for their innovative approaches and reliable performance metrics. Honeywell’s valves, for instance, often exceed industry standards, showcasing exceptional temperature control and energy conservation features.

In terms of innovation, top brands are continuously enhancing their product offerings. A recent study by TechNavio highlighted that companies investing in advanced materials and smart technologies are experiencing a market growth rate of 6.5%. This trend is exemplified by the emergence of digitally controlled valves that offer real-time monitoring and diagnostics, increasing efficiency and providing users with valuable data for maintenance and optimization. Brands like Caleffi are pioneering this technology, ensuring their products not only perform well but also contribute to a more sustainable future.

When choosing a manufacturer for thermostatic blending valves, it's essential to consider several key factors that can affect product performance and reliability. First and foremost, the manufacturer's reputation in the industry plays a crucial role; companies with extensive experience and a solid track record in producing high-quality valves will likely provide superior products. Additionally, examining the materials used in production is vital, as high-grade materials will enhance durability and resistance to various environmental factors.

Furthermore, the manufacturer’s commitment to innovation and technology can significantly influence the performance of blending valves. Manufacturers that invest in research and development are more likely to offer advanced features, such as precision temperature control and automated systems, which can improve efficiency in applications. Lastly, customer service and support should not be overlooked; responsive and knowledgeable support can greatly enhance the user experience and ensure any potential issues are resolved quickly. By taking these factors into account, businesses can make informed decisions that align with their operational needs and enhance overall performance.

Selecting the right manufacturer for thermostatic blending valves is a critical decision that can significantly impact operational efficiency and safety. Studies indicate that the quality of thermostatic blending valves directly correlates with system performance and maintenance costs. For instance, the Global HVAC Market Report by MarketsandMarkets shows that high-quality valves can improve energy efficiency by up to 25%, translating into substantial cost savings for businesses.

Furthermore, opting for a reputable manufacturer ensures compliance with industry standards and certifications. According to a report by Allied Market Research, nearly 70% of HVAC systems fail to meet efficiency standards due to subpar components. Manufacturers that adhere to rigorous production protocols and quality assurance processes tend to produce more reliable and durable products. This not only enhances the longevity of the systems but also minimizes the risk of costly breakdowns, emphasizing the importance of manufacturer selection in the long run.

| Manufacturer Type | Material | Temperature Range (°C) | Flow Rate (L/min) | Warranty (Years) | Energy Efficiency Rating | Price ($) |

|---|---|---|---|---|---|---|

| Standard | Brass | 10 - 65 | 30 | 5 | A | 150 |

| Premium | Stainless Steel | 5 - 70 | 50 | 10 | A++ | 250 |

| Economy | Plastic | 10 - 60 | 20 | 2 | B | 75 |

| Industrial | Ductile Iron | 0 - 100 | 100 | 15 | A+++ | 500 |