Choosing the right Aluminum Wire Coating can significantly impact performance and durability. "The quality of the coating determines the wire's longevity in challenging environments," says industry expert Dr. Emily Lawson. She emphasizes the importance of selecting a coating tailored to specific applications.

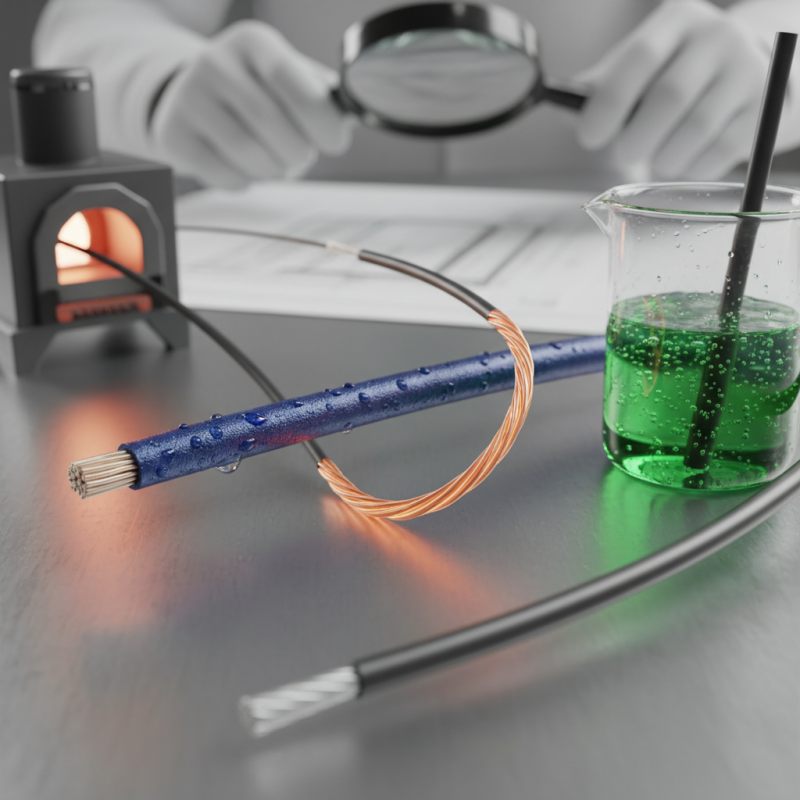

Various coatings are available, each with unique properties. Some offer outstanding corrosion resistance, while others excel in high-temperature settings. The right choice hinges on the use case. For instance, marine applications may require coatings that withstand saltwater. On the other hand, industrial settings might benefit from coatings resistant to chemicals.

It's easy to overlook details when selecting an Aluminum Wire Coating. However, the wrong choice can lead to costly repairs or replacements. Consider the environment and end-use carefully. Reflecting on past experiences can aid in making an informed decision, ensuring the longevity and reliability of your aluminum wire systems.

Aluminum wire coatings serve a crucial role in various applications. They protect wires from corrosion and enhance durability. A recent industry report shows that 70% of failures in electrical systems are due to inadequate coatings. This highlights the importance of selecting the right coating for specific environments.

Different coatings offer varied properties. For instance, some are designed for high-temperature environments, while others provide superior moisture resistance. Understanding the operational environment is essential. Rough conditions may demand thicker, more robust coatings. However, an overly thick layer can lead to flexibility issues.

Consider the trade-offs. A too-thin coat may lack protection, but a too-thick one can impact performance. Moreover, some coatings may contain materials that could lead to compliance issues later. Balancing these factors is key. Reflecting on the choices can ensure longevity and reliability in wire applications.

This chart illustrates the different types of aluminum wire coatings available in the market and their respective properties. Understanding these properties can help you make an informed decision based on your specific requirements.

When selecting aluminum wire coatings, it’s crucial to understand the different types available. Common options include enamel, PVC, and polyurethane coatings. Enamel coatings offer excellent insulation and are often used in electrical applications. PVC coatings provide good protection against moisture but can be less flexible. Polyurethane coats are durable, offering abrasion resistance, yet they may not be suitable for high-temperature environments.

Tips: Consider your environment. If you're in a humid area, go for coatings with moisture resistance. In contrast, if flexibility is key, prioritize those that adapt well.

Different coatings have distinct strengths and weaknesses. Sometimes, it’s hard to decide which one fits best. For example, enamel might crack under stress, while polyurethane can degrade in extreme heat. Think about your specific needs before making a choice.

Tips: Check the environmental conditions where you plan to use the wire. This will guide your decision. Also, consider future applications. Will you need a different coating later? Make sure you plan ahead!

When selecting aluminum wire coatings, several factors come into play. The environment where the wire will be used is crucial. For example, outdoor applications may require coatings that withstand UV rays and moisture. According to industry reports, about 40% of failures in aluminum wiring are due to inadequate protection against environmental factors.

Coating thickness is another important aspect. A thicker coating often means better durability but can also impact flexibility. Research indicates that even a minor increase in thickness can improve resistance to corrosion by nearly 30%. However, this does not apply universally. Some projects may suffer if the wire becomes too rigid.

Lastly, cost considerations cannot be ignored. The materials used in coatings can vary significantly in price. It's essential to balance durability with budget constraints. Sometimes, cheaper coatings may lead to higher maintenance costs over time. A study showed that 25% of businesses overspend on initial coating choices without factoring in long-term performance. Selecting the right aluminum wire coating thus involves careful evaluation of these key factors.

Choosing the right aluminum wire coating is crucial for specific applications. Different coatings serve distinct purposes. Common options include anodized, vinyl, and polyurethane coatings. Each has unique properties that affect performance and durability.

For instance, anodized coatings provide excellent corrosion resistance. They are ideal for outdoor applications. According to industry reports, anodized wires can last up to 30% longer than untreated wires in harsh environments. Conversely, vinyl coatings offer insulation and protection in electrical applications. The National Electrical Manufacturers Association (NEMA) states that vinyl coatings can reduce electrical loss by 15% in some cases.

Polyurethane coatings are known for their flexibility and abrasion resistance. They work well in automotive and aerospace sectors. However, choosing the wrong coating can lead to performance issues. Some customers find that specific coatings do not adhere properly under extreme temperatures. Understanding these details can help ensure the right choice for your project.

When selecting aluminum wire coatings, understanding maintenance and longevity is crucial. According to a report by the Aluminum Association, the average lifespan of aluminum wire can exceed 30 years with proper coating and care. However, not all coatings are equal. Some may require more frequent inspections and maintenance.

For instance, thermoplastic coatings provide a durable barrier against moisture and chemicals. Yet, they may not resist UV degradation as effectively as others. A study by the Institute of Electrical and Electronics Engineers indicates that UV exposure can reduce the lifespan of certain coatings by up to 50%. Regularly checking for signs of wear can prevent costly replacements.

Environmental factors also play a role in the longevity of coated products. In humid climates, corrosion risk increases. A protective layer can help, but it demands attention. Over time, coatings may crack or peel. Such issues can compromise the wire's integrity. Periodic maintenance, though sometimes overlooked, can extend the lifespan significantly. Neglecting it can lead to unexpected failures, which raises safety concerns.

| Coating Type | Durability | Corrosion Resistance | Temperature Range (°C) | Cost Efficiency |

|---|---|---|---|---|

| Polyester | High | Good | -60 to 130 | Moderate |

| Polyvinyl Chloride (PVC) | Moderate | Excellent | -20 to 90 | Low |

| Fluoropolymer | Very High | Excellent | -200 to 260 | High |

| Anodized | High | Good | -30 to 200 | Moderate |

| Epoxy | High | Fair | -40 to 120 | Low |