In an era where automation and precision are paramount, the global automatic valve market is poised for significant growth, projected to reach USD 30 billion by 2025 with a compound annual growth rate (CAGR) of 6.5% from 2020 to 2025. Automatic valves are crucial components in various industries, including oil and gas, water and wastewater, and power generation, where they enhance operational efficiency and safety by allowing for remote and automated control. According to a recent industry analysis by Research and Markets, the increasing demand for smart valves that integrate with IoT systems is driving innovations in automatic valve technology. As manufacturers and businesses seek to optimize their processes and reduce downtime, understanding the intricacies of automatic valves becomes essential. This comprehensive guide aims to equip global buyers with the necessary insights to navigate this dynamic market and make informed purchasing decisions in 2023.

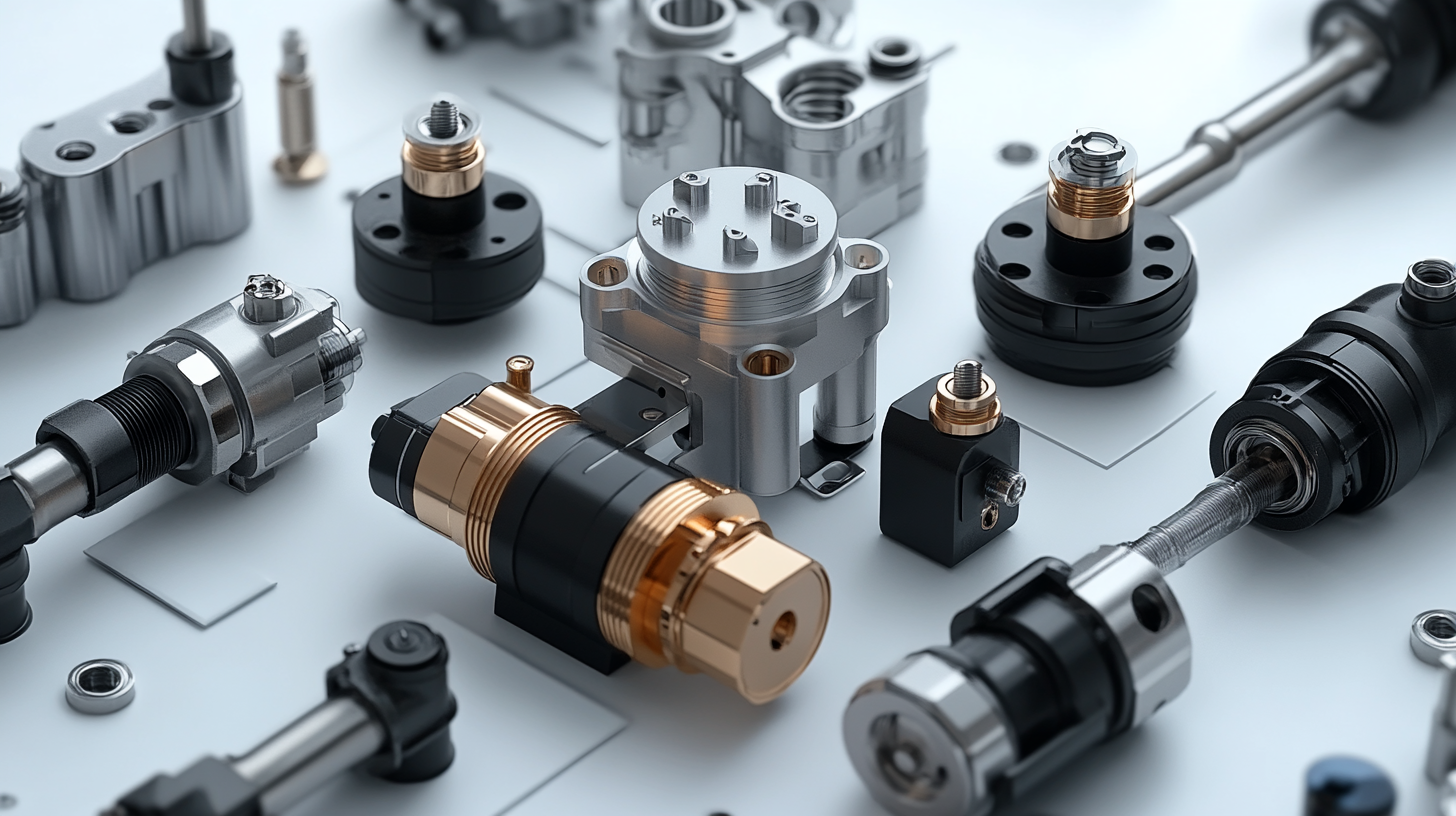

Automatic valves are essential components in various industries, allowing for the efficient control of fluid flow without the need for manual intervention. Understanding the basics of these valves starts with recognizing their types. Common categories include ball, gate, globe, butterfly, and check valves, each serving distinct functions. For instance, ball valves are favored for their ability to provide tight seals and quick shut-off, making them ideal for applications where flow control is critical. In contrast, check valves prevent backflow, ensuring that fluids flow in the intended direction, which is crucial for maintaining system integrity.

The functions of automatic valves extend beyond mere flow regulation. They can also facilitate pressure relief, prevent contamination, and optimize energy usage within a system. By automating these processes, industries can improve operational efficiency and safety. Moreover, modern advancements in technology have led to the development of smart automatic valves, equipped with sensors and communication capabilities to enhance monitoring and control. This evolution not only boosts performance but also aids in predictive maintenance, reducing downtime and operational costs. Understanding these basic parameters is vital for global buyers looking to make informed decisions when investing in automatic valves in 2023.

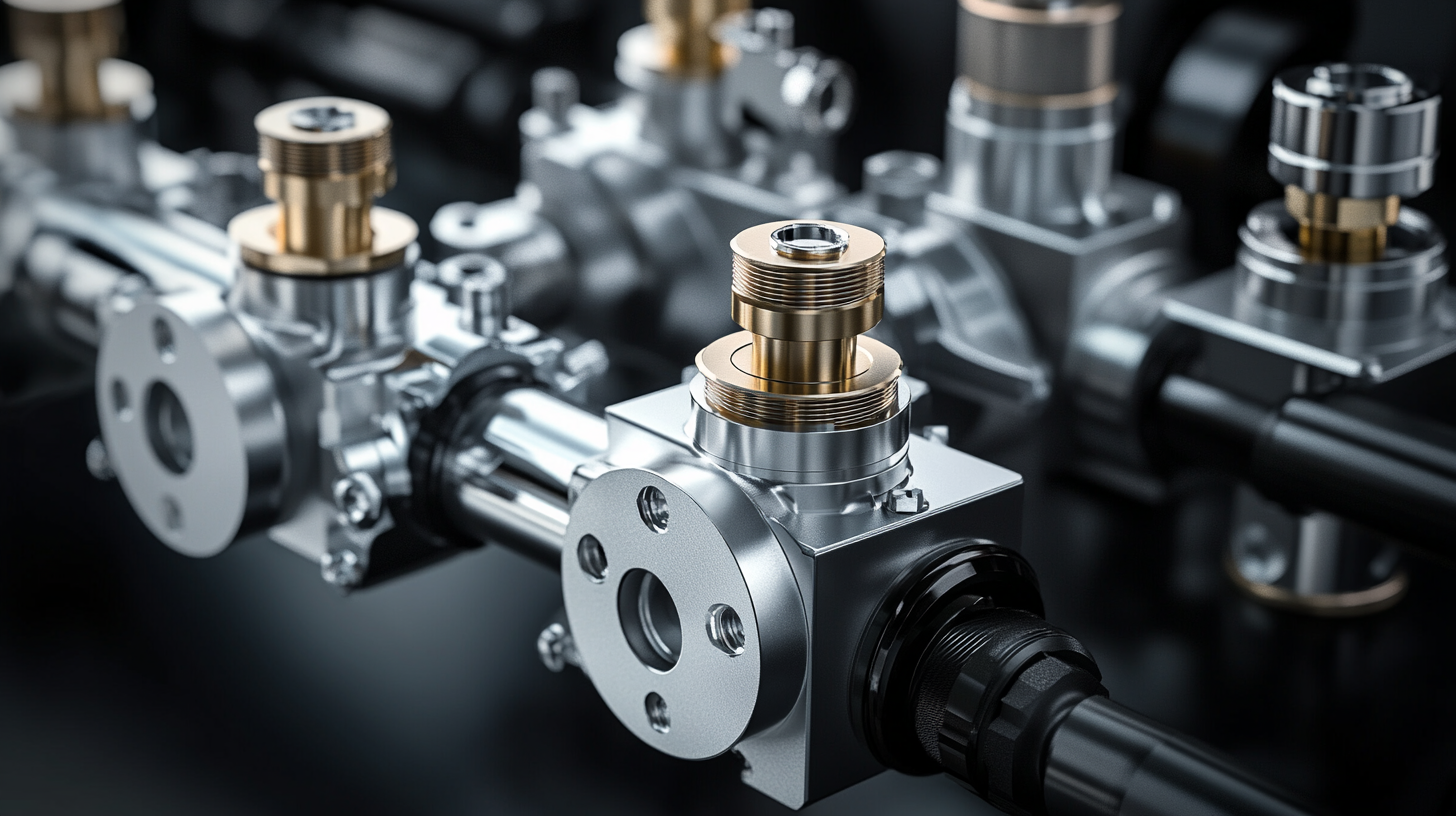

When selecting automatic valves, several key factors must be considered to ensure optimal performance and reliability. Understanding the specific application and environment where the valves will be used is crucial. This includes assessing parameters such as pressure, temperature, and fluid characteristics. For instance, the valve material should withstand the corrosive nature of the fluids it will control, which can significantly influence its lifespan and maintenance needs.

Another important aspect is the type of actuator that operates the valve. Electric, pneumatic, and hydraulic actuators each come with their own advantages and limitations, making it essential to choose one that aligns with the operational requirements and constraints of your system. Moreover, consider the control options available, as advanced automation and integration capabilities can enhance efficiency and control in complex processes. By focusing on these key factors, global buyers can make informed decisions that meet their specific needs and ensure the longevity and efficiency of their automatic valve systems.

In 2023, the landscape of automatic valve systems is rapidly evolving, driven by advancements in technology and increasing demand for efficiency and reliability across various industries. One of the most significant trends is the integration of smart technologies into valve systems, allowing for real-time monitoring and control. These smart valves utilize IoT sensors and data analytics to optimize performance, reduce downtime, and minimize maintenance costs. As automation continues to dominate industrial processes, the adoption of these intelligent systems is becoming essential for global buyers looking to enhance their operational efficiency.

Moreover, sustainability is a key focus area in the development of automatic valve technologies. Manufacturers are now prioritizing eco-friendly designs that reduce energy consumption and support greener operations. Innovations such as advanced materials and energy-efficient actuators are emerging, making automatic valves not just more effective but also more environmentally friendly. Buyers are encouraged to consider these sustainable options as part of their procurement strategy to meet both regulatory requirements and corporate social responsibility goals. As we delve deeper into this year, understanding these trends will empower buyers to make informed decisions that align with their operational needs and sustainability objectives.

Maintaining the efficiency of automatic valves is crucial for any operation reliant on fluid control systems. According to a report by the International Society of Automation, nearly 60% of system failures can be traced back to valve issues. To combat these failures, regular maintenance practices should be implemented to ensure optimal performance. Techniques such as routine inspections, calibration, and the use of diagnostics tools can help identify potential problems before they escalate, preserving system integrity and functionality.

Moreover, data from the Valve Manufacturers Association indicates that integrating predictive maintenance strategies can reduce downtime by up to 30%. By leveraging advanced analytics and condition monitoring tools, operators can track valve performance in real-time and preempt failures. This proactive approach not only enhances reliability but can also lead to significant cost savings, allowing companies to allocate resources more efficiently. Regular training for staff on valve care and maintenance practices is also essential, as a well-informed team is key to sustaining the long-term performance of automatic valves in any industrial setting.

Navigating the global market for automatic valves in 2023 requires a strategic approach to sourcing suppliers and understanding pricing dynamics. According to a report by Market Research Future, the automatic valve market is projected to grow at a compound annual growth rate (CAGR) of 5.6%, reaching a valuation of approximately $19 billion by 2025. This growth underscores the increasing demand across various industries, including oil and gas, water treatment, and power generation, where the efficacy of automatic valves plays a crucial role in operational efficiency and safety.

When considering suppliers, buyers must evaluate not just price but also quality and reliability. A recent analysis from Technavio indicates that competitive pricing strategies, such as bulk purchasing discounts and long-term contracts, can greatly affect total procurement costs. Additionally, as the manufacturing landscape becomes more globalized, buyers have the opportunity to source from emerging markets, which may offer lower costs but require careful assessment of quality standards. Understanding supplier capabilities and market trends can significantly enhance a buyer’s ability to negotiate effectively, resulting in both cost savings and improved supply chain resilience.