An Auto Dc Pump is a vital component in various applications. These pumps operate using direct current (DC) power, which makes them efficient and reliable. They are commonly used in solar systems, automotive applications, and water circulation. The simplicity of an Auto DC Pump allows it to function without complicated controls.

While looking at the mechanics, it’s essential to consider how they convert electrical energy into mechanical energy. This conversion powers the pump’s motor, driving the impeller to move fluids. Understanding this process can seem straightforward, but the intricacies leave room for improvement. For instance, the efficiency of an Auto DC Pump can vary significantly based on the design and materials used.

Despite their advantages, Auto DC Pumps are not perfect. Users might face issues like overheating or inadequate flow rates. Reflecting on these shortcomings helps in making informed decisions. Taking time to analyze the specific needs before choosing a pump can lead to better outcomes. By understanding both their capabilities and limitations, we can utilize Auto DC Pumps more effectively.

An auto DC pump is a versatile device designed for various applications. These pumps operate using direct current (DC) power, making them ideal for off-grid systems and solar energy use. They are commonly found in aquariums, irrigation systems, and water circulation applications. The ability to run on low voltage makes them efficient and safe.

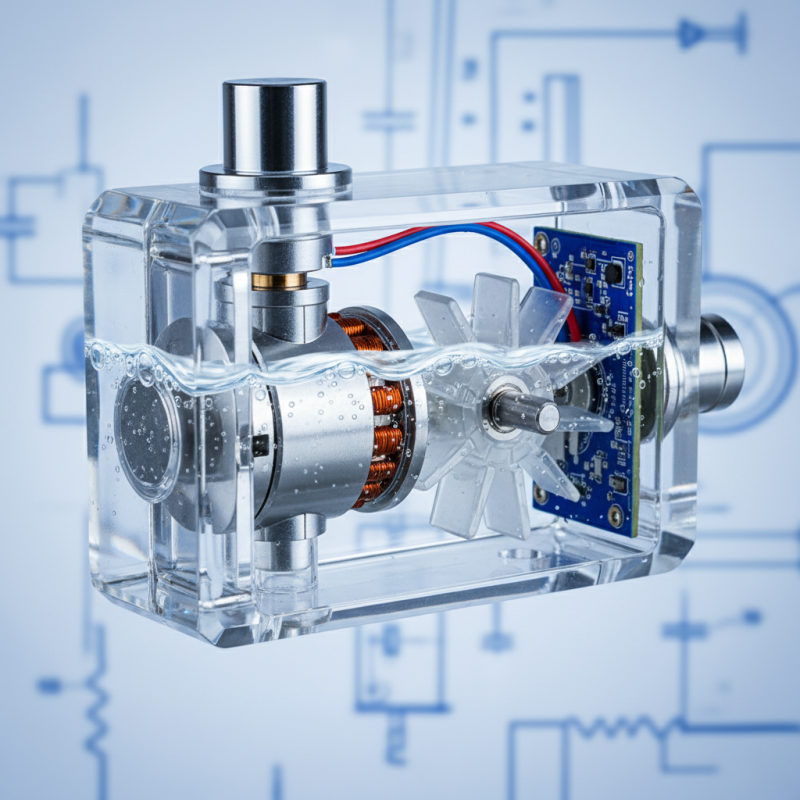

Key components of an auto DC pump include a motor, impeller, and control circuit. The motor converts electrical energy into mechanical energy, driving the impeller. The impeller, often made of durable materials, creates flow by pushing water. A control circuit regulates the pump's operation, ensuring optimal performance and efficiency. Each part must work together seamlessly. If one component fails, the entire system can suffer.

Installation of the pump may not always be straightforward. Some users struggle with placement and wiring. Addressing power supply requirements can be tricky. Users sometimes overlook water sources and pressure requirements. It's vital to consider these factors for effective operation. A little research can go a long way. The more informed users are, the better their systems will function.

This bar chart represents the performance metrics of various auto DC pumps based on their flow rate (L/min) and power consumption (W). The data reflects the average performance of several models in the market.

Auto DC pumps are becoming popular in various applications due to their efficiency. These pumps utilize direct current (DC) motors for operation. The design is quite simple but effective. When electricity flows through the motor, it creates a magnetic field. This magnetic field interacts with the coil, causing the rotor to spin.

The mechanism enables these pumps to draw liquids effectively. As the rotor spins, it creates suction. This allows the pump to move fluids through tubing or piping systems seamlessly. The controlling circuitry can adjust the flow rate, making it versatile for different tasks. In clean water systems, for example, they can efficiently manage water flow based on demand.

However, there are some challenges. The efficiency may drop if the pump is overloaded or improperly calibrated. Over time, components can wear down, affecting performance. Regular maintenance is essential to keep the pump in optimal condition. Users should be aware of these factors to prevent system failures. Understanding the inner workings of Auto DC pumps helps in troubleshooting issues effectively.

Auto DC pumps are increasingly popular in fluid transfer applications. These pumps operate on direct current, making them energy-efficient. They excel in scenarios where precision and reliability are key. With a compact design, they are easy to install in various setups. In many cases, they outperform traditional pumps in terms of power consumption.

One major advantage of Auto DC pumps is their ability to handle different fluid types. From water to more viscous substances, they are versatile. Users often report fewer maintenance issues compared to AC pumps, which can be a significant concern. This reliability reduces downtime and operational costs.

However, some users struggle with the initial setup. A lack of experience can lead to improper connections. This highlights the need for better training and guidelines. Promoting awareness about proper usage will enhance the effectiveness of these pumps. Addressing these challenges ensures that Auto DC pumps can meet the diverse needs of fluid transfer systems effectively.

Auto DC pumps have gained traction in various industries and agriculture. Their efficiency and ease of use make them a popular choice. These pumps operate using direct current, which allows for smooth and precise flow control. They can adapt well to renewable energy sources, such as solar power.

In agriculture, Auto DC pumps play a critical role in irrigation systems. Reports indicate that approximately 65% of global irrigation relies on efficient water management systems. These pumps help optimize water usage, reducing waste. Farmers can precisely target their irrigation efforts, which leads to improved crop yields and resource conservation. Studies show that implementing these pumps can increase crop productivity by up to 30%.

In industrial applications, Auto DC pumps support process cooling and wastewater treatment. Their reliability is vital for maintaining operational efficiency. However, the cost of installation and maintenance can sometimes limit their widespread adoption. Many industries still rely on traditional methods, which may not be as efficient. This gap represents a significant area for growth and reflection on how to embrace modern technology in industrial processes.

| Application Area | Specifications | Power Source | Flow Rate (L/min) | Typical Uses |

|---|---|---|---|---|

| Agriculture | 12V - 24V, submersible | Solar or Battery | 10-30 | Irrigation systems, water supply |

| Industrial | 24V, high pressure | DC Motor | 20-50 | Cooling systems, process water |

| Aquaculture | 12V, corrosion-resistant | Battery operated | 5-15 | Water circulation, aeration |

| Residential | 12V, compact | Household battery | 8-20 | Water transfer, garden fountains |

Auto DC pumps are essential in various applications, including automotive and renewable energy sectors. Industry standards for these pumps focus on efficiency ratings and performance metrics. The efficiency of an Auto DC pump often dictates its energy consumption and operational lifespan. Reports indicate that high-efficiency models can achieve efficiency ratings above 85%. However, many pumps still struggle to meet these standards consistently.

In practice, the performance of an Auto DC pump can vary widely among different manufacturers. A reliable efficiency rating is crucial for users. The Eco Label program highlights pumps that meet or exceed industry standards. Yet, not all products qualify. This can lead to confusion and disappointment for buyers who expect high performance.

Data from the Fluid Power Journal reveals that a significant number of pumps in use today operate below their optimal efficiency. This inefficiency often goes unnoticed until a failure occurs. Regular monitoring and maintenance are vital for ensuring that pumps operate at peak performance. Addressing these gaps is essential for manufacturers as well as users in the market.